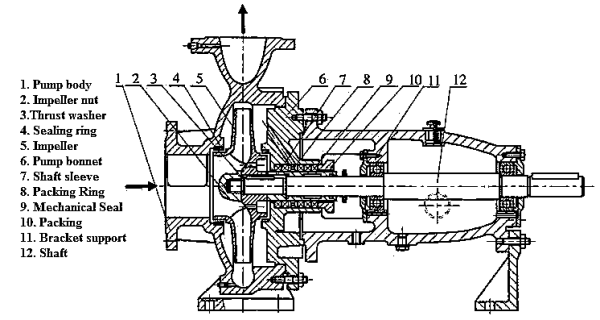

2 Main components of single-stage centrifugal pump: impeller

The impeller is the only work component, and the pump does work on the liquid through the impeller. There are three types of impellers: closed, open and semi-open. The closed impeller consists of blades, front cover and rear cover. The semi-open impeller consists of blades and rear cover. The open impeller has only blades and no front and rear cover plates. Closed impeller is more efficient, open impeller is less efficient

3 Main components of single-stage centrifugal pump: sealing ring

The function of the sealing ring is to prevent the internal leakage and external leakage of the pump. The sealing ring made of wear-resistant material is inlaid on the front and rear cover plates of the impeller and the pump casing. Can be replaced after wear.

4 Main components of single-stage centrifugal pump: shaft and bearing

The impeller is fixed at one end of the pump shaft, and the coupling is installed at the other end. According to the size of the pump, the bearing chooses rolling bearings and sliding bearings.

5 Main components of single-stage centrifugal pump: shaft seal

There are generally two types of shaft seals: mechanical seals and packing seals. Generally, the pumps are designed to be able to install both packing seals and mechanical seals.

Vertical Single Stage Centrifugal Pump Installation Instructions

1. Before installation, check whether the fasteners of the unit are loose, and whether the flow passage of the pump body is blocked by foreign objects, so as to avoid damage to the impeller and pump body when the pump is running.

2. The weight of the pipeline should not be added to the pump during installation, so as not to deform the pump.

3. The anchor bolts must be tightened during installation to avoid the impact of vibration on the pump performance during startup.

4. For the convenience of maintenance and safe use, a regulating valve is installed on the inlet and outlet pipelines of the pump and a pressure gauge is installed near the pump outlet to ensure the operation within the rated head and flow range, and ensure the normal operation of the pump and the growth of the pump. service life of the pump.

5. After the vertical single-stage centrifugal pump is installed, turn the pump shaft, and the impeller should have no friction noise or jamming phenomenon, otherwise the pump should be disassembled to check the cause.

6. The pump is divided into two types: hard connection installation and soft connection installation (see connection method).

Preparation before starting vertical single-stage centrifugal pump

1. Test whether the rotation of the motor is correct. It rotates clockwise from the top of the motor to the pump. The test time should be short to avoid wear of the mechanical seal.

2. Open the drain valve to fill the entire pump body with liquid, and close the exhaust valve when it is full.

3. Check whether all parts are normal.

4. Drive the pump by hand to make the lubricating fluid enter the end face of the mechanical seal.

Working conditions of vertical single-stage centrifugal pump

Suction pressure ≤ 1.0Mpa, or the maximum working pressure of the pump system ≤ 1.6Mpa, vertical single-stage centrifugal pump suction port pressure + pump head ≤ 1.6Mpa. The static pressure test pressure of the pump is 2.5Mpa. Please specify the system working pressure when ordering. When the working pressure of the pump system is greater than 1.6Mpa, it should be put forward separately when ordering, so that the over-current part and the connecting part of the pump are made of cast steel during manufacture.

Ambient temperature <40℃, relative humidity <95%.

The volume content of solid particles in the conveyed medium does not exceed 0.1% of the unit volume, and the particle size is less than 0.2mm.

Note: If the medium used is with fine particles, please specify when ordering, so that the manufacturer can use the wear-resistant mechanical seal.

Single Stage Centrifugal Pump Manufacturer

The SHOUFEI Pump, CHINA manufacturer odm oem supplies, Provide single stage pipeline circulating pump in a high quality, anti-corrosive centrifugal pump that is perfect for clean water applications. The pump is made of stainless steel and has a single suction design that makes it easy to install and operate.

SHOUFEI single stage single suction centrifugal pump Manufacturer, has clean water pump with excellent anti-corrosion properties. It is made of high quality materials and has a sturdy construction. The pump is designed for continuous operation and can be used in a wide range of applications.

The Single-stage Pipeline Circulating Pump is a great choice for those who are looking for a quality, single stage, single suction, clean water, anti corrosive centrifugal pump. This pump is made from high quality materials and is designed to provide years of trouble-free operation. The pump features a compact design and is easy to install.

SHOUFEI Pump one-stop Pump factory for many years, Shoufei Pump has been committed to manufacturing a variety of high-quality water valves. We continue to expand our product line, starting with brass fittings and valves. With on-site production processes and readily available durable materials, we export water valve components to 78 countries to meet growing demand. As a result of our efforts to innovate and improve quality control, our products are strongly supported by important markets and exported to 78 countries. As we remain committed to serving our customers, we expand our product line to face new trends and adapt to customer needs with improved OEM support.